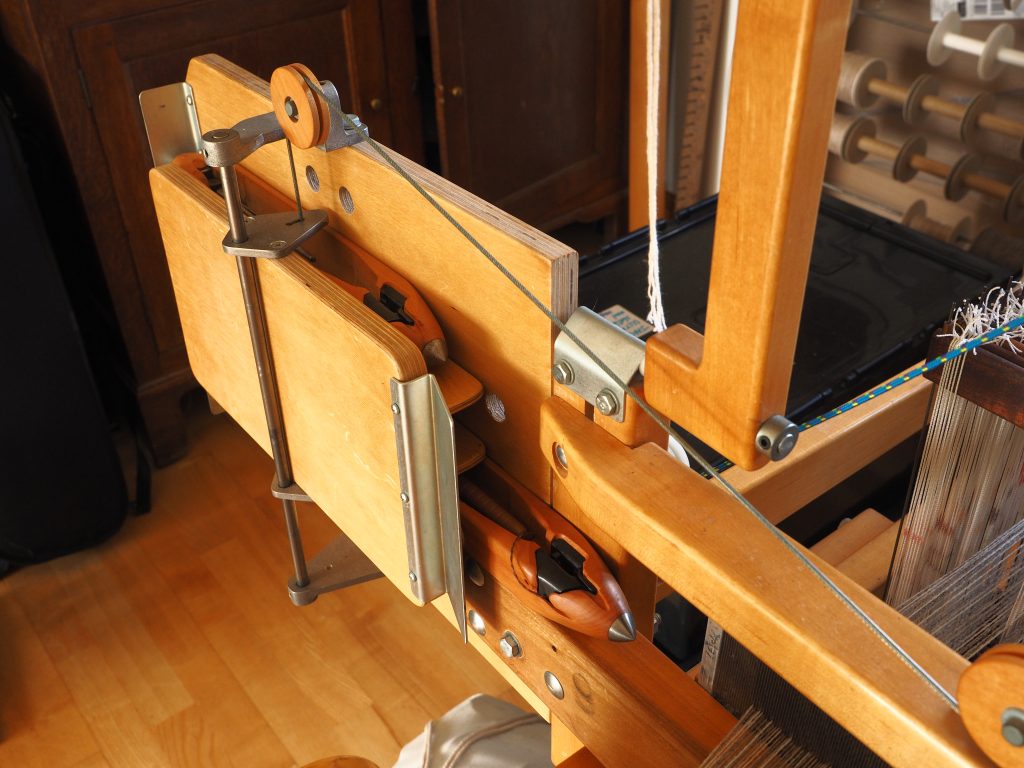

AVL hand-looms straddle the high-end domestic – low-end industrial market, this one is their Technical Dobby Loom, built sometime around the mid-1990’s. Quite a room-full, it’s classed as a “production” loom: capable of taking long warps (the biggest I’ve had on so far is 30 metres); with flying-shuttles for fast weaving; automatic yarn-tensioning; and a mechanical dobby unit that controls its 24 shafts.

The dobby will raise any shaft that has a peg inserted in the current bar… no peg and that shaft stays down.

like 24-bit binary computer data

The chain of dobby bars defines all the steps required to weave one repeat of the pattern. Once each weft “pick” has gone in, the chain indexes round one notch to select the next bar in sequence.

Setting up this type of loom is quite a big undertaking, the warp is built-up in 2-inch wide sections from a rack of spools, then each “end” (warp thread) is threaded through the shafts and the 40-inch reed. To make all this worthwhile, it makes sense to load a lo-ooong warp and weave several items in the one batch.

Once set up though, the AVL tends to run very smoothly. It’s a well-engineered, solid workhorse that does a consistent job and keeps steady tension over the full batch. It’s basically, a nice machine to work with.

A few early pieces made when I was getting to know this loom, from the left…

- Tree-motif double cloth in plant-dyed (Tony Lambert) 2/18 worsted. This was entered in the 2018 RHS Handcrafts competition.

- Silk scarf for my lovely… interleaved twill in 2/16 spun silk / lycra, with cosy neck section in 3/1 silk chenille.

- Shawl in sponge-weave, showing-off a couple more of Tony’s rich natural colours.